|

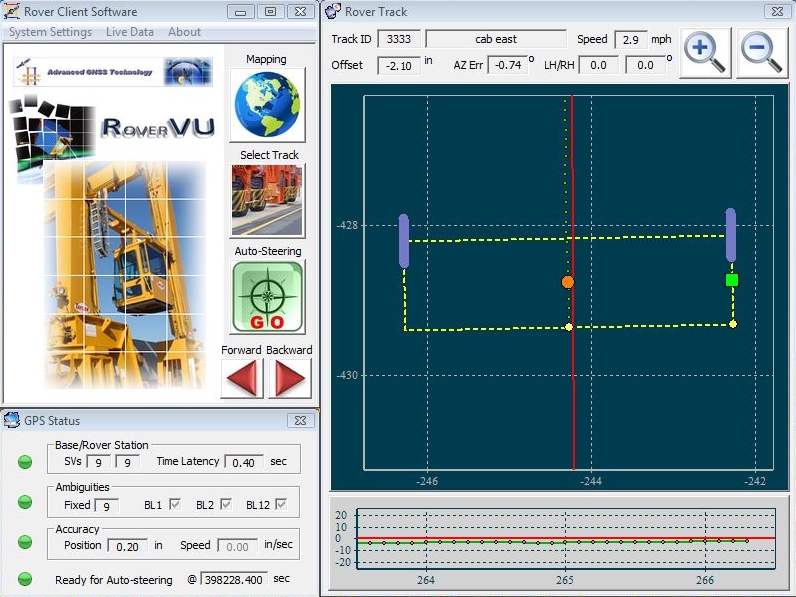

SteerVu™ provides the GNT

auto-steering logic controller with high-accuracy, high-performance GPS

navigation solutions and attitude information. SteerVu™ steers vehicles

such as rubber-tired gantry (RTG) cranes, cargo transport vehicles, lawn

mowers and tractors using a “map and match” mode of operation. SteerVu™ is

designed for use in repetitive navigation applications. SteerVu™ consists of a Base Server

(BaseVu) and a Rover Client (RoverVu). BaseVu is connected with one or

more GPS Base Stations. BaseVu receives raw GPS observations from the Base

Station(s) in real-time. The status of the Base Station(s) is constantly

monitored. RoverVu is installed on a vehicle and is connected with BaseVu.

Upon receiving a request from RoverVu, BaseVu transmits the raw GPS

observations received from the Base Station(s) to RoverVu.

Map and match programming allows a human operator to map a navigation path

by driving the vehicle over the path to be matched while RoverVu is in

“map” mode. During map mode, RoverVu records and stores GPS positioning

data which allows RoverVu to autonomously reproduce the mapped path.

Multiple paths can be mapped and stored for a project site. Each path is

uniquely defined by the GPS coordinates within the path. Navigation paths

are stored locally in RoverVu memory and can be downloaded to a removable

USB flash memory drives.

With the navigation paths stored, the vehicle is capable of retracing the

mapped paths whenever necessary. When the vehicle is in the vicinity of

the desired path, the operator can select the desired navigation path to

be matched from a list of paths saved for the site in RoverVu memory. Once

the path has been selected and connection to BaseVu has been achieved, the

operator moves the vehicle near the start of the navigation path. The

operator then places the vehicle in automatic operation mode and the

vehicle enters the navigation path, moving to the desired locations

automatically.

The GPS RTK (Real-Time Kinematic) technique allows the vehicle to know

precisely where it is on the surface of the earth to a positional accuracy

of better than one inch. Under purely robotic control, the vehicle will

wander off course due to errors caused by wheel slippage, uneven terrain,

and other mechanically-induced errors. RoverVu makes use of its GPS RTK

navigation solutions and attitude information to correct for errors in the

vehicle control system. In typical conditions where satellite visibility

is favourable and the vehicle is well calibrated, the navigation path can

be tracked to better than plus or minus two inches. |